Atlas Copco is a leading manufacturer of industrial assembly equipment for automotive assembly workstations. One of our key product areas includes equipment used for handling, inserting and tightening screws into vehicle components. Targeting efficiency and quality increase, as well as manual labor cost reduction, we are looking for solutions to automate screw sorting and feeding in automotive assembly workstations.

Opportunity overview

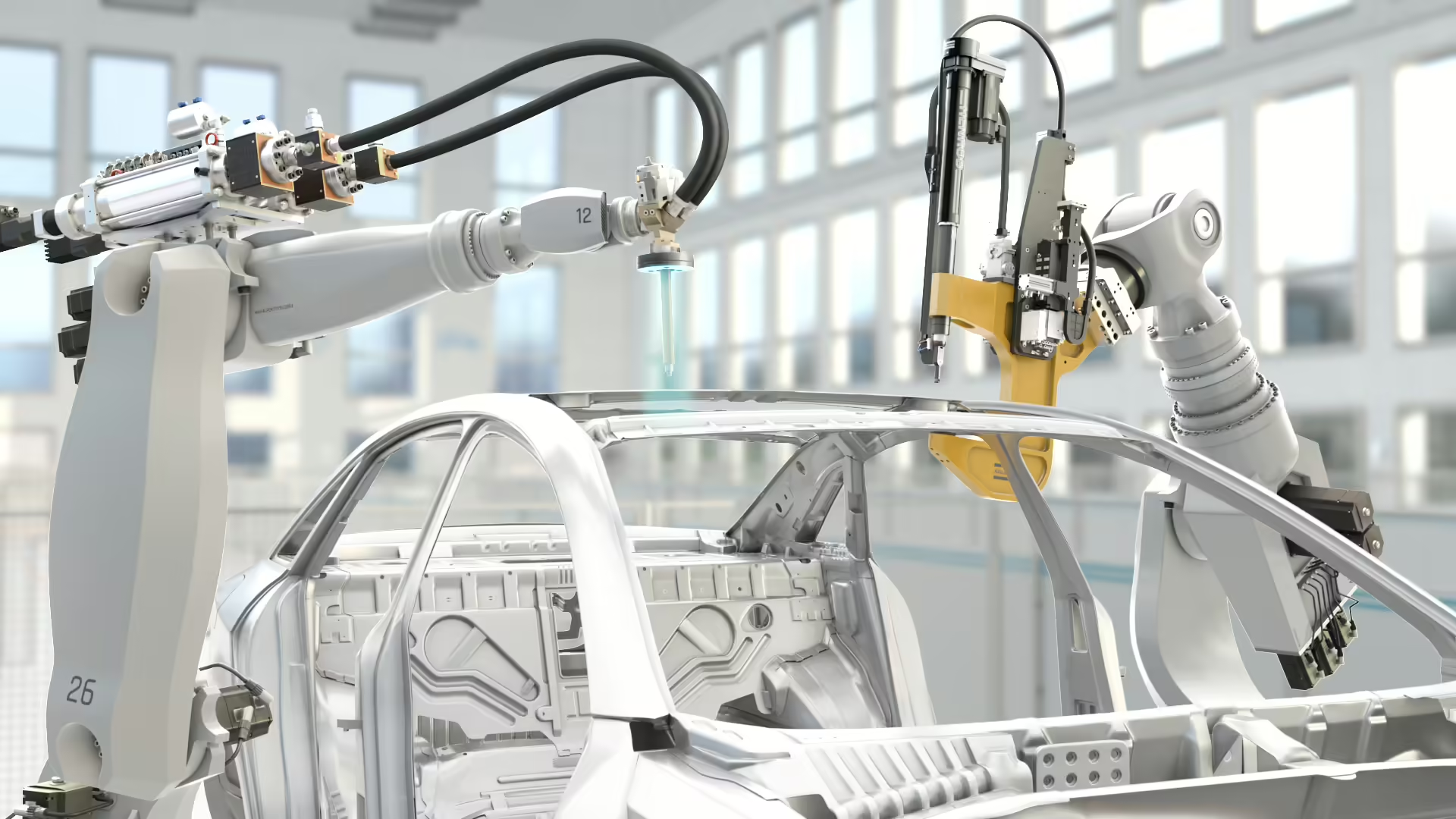

Atlas Copco’s Industrial Assembly Solutions division is a leading provider of joining and dispensing solutions for various vehicle painting and e-mobility applications. To address the growing importance of value-chain wide sustainability, we are looking for solutions to help our customers achieve their sustainability targets related to material savings, car weight reduction and material and process efficiency.

Edge AI Solutions for Industrial Assembly with Atlas Copco

Atlas Copco’s Industrial Assembly Solutions division is a leading provider of joining and dispensing solutions for various vehicle painting and e-mobility applications. Some of our customers prefer not to share any data…

Learn more

Sustainable Elevator Hydraulics with KONE

Hydraulic elevators are cost-effective products for the low-rise elevator segment. However, they are not the preferred solution due to poor sustainability and lower ride comfort. To overcome these disadvantages, KONE, a global…

Learn more

Wear-resistant Coating Solutions with Autoliv

As concerns for ecological footprints rises in the automotive industry, the ambition is to find alternatives to electroplated surfaces on steel safety components. A nickel-chromium layer on a seatbelts buckle, for example,…

Learn more