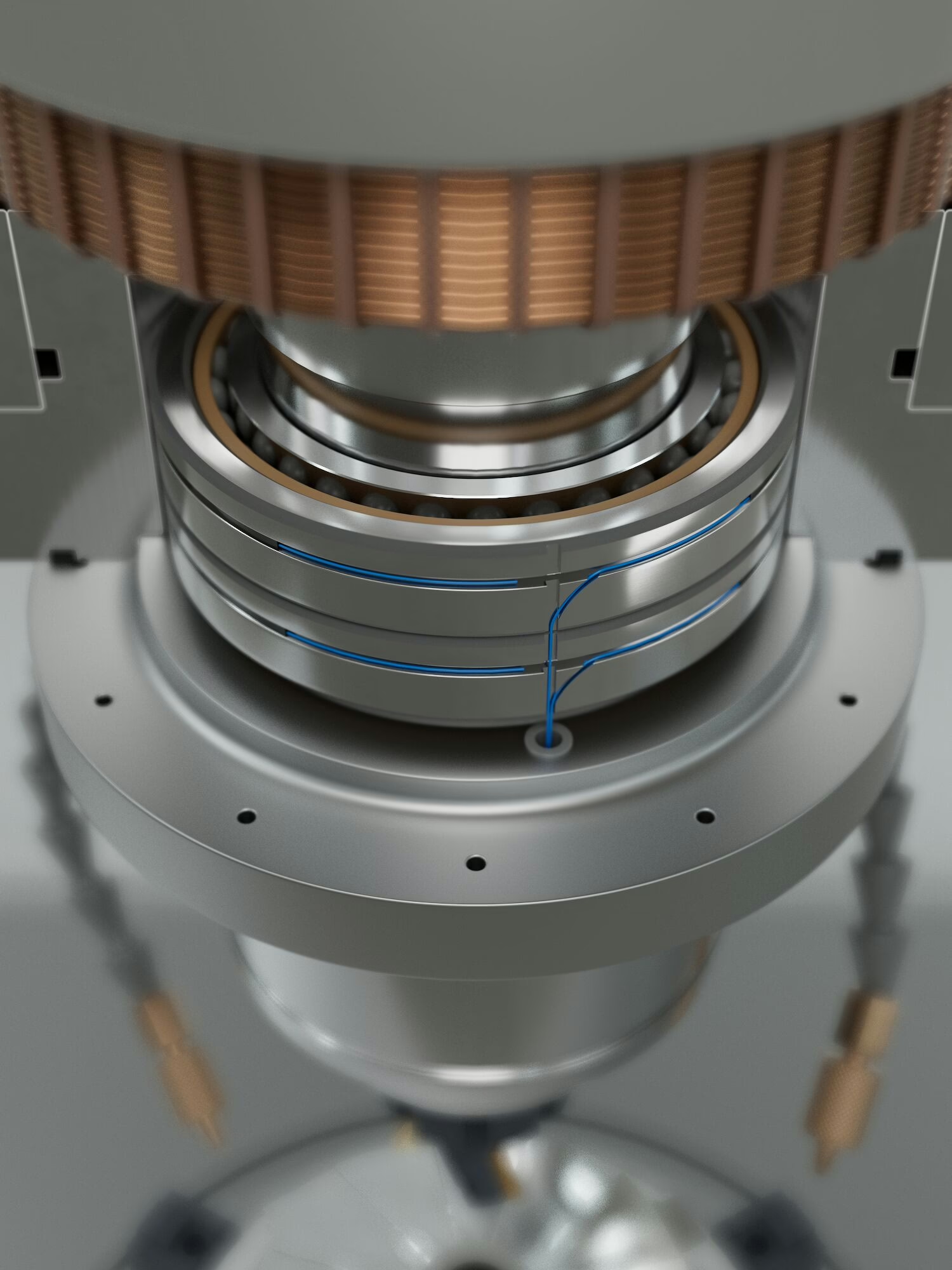

We are seeking a cost-effective, scalable optical interrogator solution for fiber optic sensor (FOS) bearings, enabling advanced condition monitoring across industrial applications with long-term series production potential.

Opportunity overview

The challenge is to advance the capabilities and accessibility of FBG interrogators for dynamic real-time sensing. These interrogators, which serve as both the light source and receiver for embedded fiber optic sensors, are essential for capturing real-time strain and temperature data, supporting smarter, data-driven maintenance strategies in bearings. The fiber optic interrogator market is a niche and rapidly evolving one. There is a growing need for robust, compact, and flexible solutions that can be produced at scale and integrated into diverse industrial environments. By addressing this challenge, we aim to drive innovation in condition monitoring and unlock new opportunities for predictive maintenance and asset optimization.

Today, interrogators are often limited by their technical complexity and integration requirements, restricting their deployment to select applications. Our vision is to develop together a compact interrogator that meets demanding requirements for sampling frequency [Hz], number of channels, wavelength resolution [pm], and onboard computational power availability [flops]. We are open to a wide range of technological approaches—whether traditional electronics, photonics chips or another novel solution—to maximize solution diversity. Use cases include dynamic industrial bearing monitoring, with the potential to expand into automotive and structural health monitoring. Interoperability with SKF’s digital platforms and compliance with relevant industrial standards are important.

Summary of the Requested Solution

We are seeking a cost-effective FBG interrogator solution for dynamic, real-time fiber optic sensing applications, designed to match predefined size and integration requirements. The ideal stand-alone hardware solution should meet the specified technical requirements, enabling robust integration into industrial environments and interoperability with SKF’s digital platforms. We welcome a wide range of technological approaches that support scalable series production and advanced condition monitoring. Importantly, we expect more than just conceptual proposals—suppliers should be prepared to provide a functional hardware prototype for evaluation as part of the engagement process.

Your opportunity with SKF

SKF is the world’s leading bearing manufacturer, with 17,000 distributors in 130 countries. Collaborating with SKF on providing wireless condition monitoring solutions offers an opportunity to contribute to making industries reduce downtime, improving equipment longevity and making industrial operations more resource efficient. We want to work together and provide you with valuable learnings that enable your company further opportunities within the industry.

Examples we're looking for

Functional Multi-Channel Interrogator

A hardware solution that delivers high sampling frequency and multi-channel capability in the given form factor, suitable for integration into bearing assemblies and capable of handling multiple FBG sensors for strain and temperature measurement.

Photonics Chip-Based Interrogator

A cost-effective interrogator leveraging photonics chip technology to achieve cost-effective units at scale, while meeting industrial requirements for robustness, wavelength resolution, and onboard data processing.

Flexible, Scalable Electronics Platform

A modular interrogator platform based on traditional electronics, designed for easy adaptation to different industrial environments and scalable from pilot to high-volume production, with clear pathways for integration into SKF’s digital ecosystem.

Grease Collection Solutions with SKF

SKF is looking to enable large scale recycling of used grease, but the collection of it is forming a bottleneck. In various heavy-duty applications, used lubrication grease is currently collected manually, by…

Learn more

AI-Powered Sourcing Efficiency with Autoliv

Autoliv is seeking to enhance its procurement efficiency by automating and optimizing the management of its global RFQs (request for quotation) through innovative bundling strategies. Submission deadline for the opportunity: 15 June…

Learn more

Preventive Maintenance with Husqvarna Group

Husqvarna Group aims to develop a scalable, digital, and intuitive preventive maintenance system that improves efficiency and consistency across our global operations. By leveraging insights from dealers, customers, and digital sources, we…

Learn more