Shippers and carriers see tremendous potential to further optimize and automate their transports and improve the efficiency of their supply chains through combining vehicle position data from heavy vehicle data and telematics systems with the availability of integration and mediation platforms. By enriching Scania’s vehicle data in innovative ways and by securing interoperability within the supply chain, we can drive the transformation of transport-related data services and introduce new service capabilities to Scania’s customers.

Opportunity overview

Shippers want to improve the punctuality of scheduled arrivals and unloading in their end-to-end supply-chains. For this, they need to get near real-time ETA and see detailed transportation history in order to optimize the route and stops together with selected contractors, typically carriers. However, time is currently wasted due to the inability to integrate vehicle and time slot scheduling data. Instead, extensive manual administration is required to optimize the transport operations across their supply chains.

By integrating enriched vehicle position data with transport management system data, shippers could optimize the delivery arrival precision to unloading time slots, get ETA alerts to automate docking and departure guidance, as well as to optimize trip duration in near real-time of ongoing delivery missions, including routes and stops. Furthermore, excess waiting times at loading and unloading points could be minimized with increased transparency to the exact locations of the trucks in the supply chain. For shippers, improved supply chain transparency also enables to monitor the driver behaviour on a contractor level in order to compare the performance of different carriers. Carriers’ administrations, on the other hand, gain more support for dealing with on-the-road penalties.\n\nWe at Scania envision solutions that are able to integrate vehicle position data, time slot data, and e-CMR data. We are especially interested in solution providers that can work with the data already in the back-end, including e.g. visualization engines that come before the actual interfaces. Therefore, the potential solution providers should have technical expertise of data analysis and tools. In addition, marketing and sales capabilities are considered as a benefit, as we are looking to collaborate with solution providers that can work with Scania and Scania’s customers close to distribution and logistics use cases, partly outside of Scania’s current service offering.

Your opportunity with Scania

Working with Scania, a world-leading provider of transport solutions, the selected solution providers will get support from Scania’s business development and data analytics resources, as well as increased visibility across Scania’s sales network. As Scania is especially looking for R&D and technological capabilities, co-development is the preferred solution collaboration model. To reach the vision Scania is aiming for combination of different systems into system-of-systems, a combination of co-development partners is also likely, as well as co-marketing of the service offering together with Scania in a joint go-to-market scenario. Eventually, if the relationship with Scania proves successful, there are integration opportunities to Scania in the longer term. “

Examples we're looking for

Integration and interoperability with TMS

Integration and interoperability between multiple vehicle telematics data systems and transport management systems for shippers as well as carriers.

Supply chain visibility

Vehicle-related events and/or other aggregated vehicle data visible in supply chain control towers for shippers and carriers.

Supply chain network optimization and automation

Vehicle data combined with other transport management system-related data to optimize and automate the supply chain.

Open Fleet Management for Autonomous Intralogistics with Scania

At Scania, we see a growing need to connect and manage indoor robots of different brands and types from a single system to optimize indoor material movement and the flow of warehouse…

Learn more

Sustainable Caps and Closures with Stora Enso

Stora Enso constantly works on sustainable and recyclable packaging options for various industries and applications worldwide. We want to co-develop sustainable caps and closures to make our fiber-based beverage packaging and tubes…

Learn more

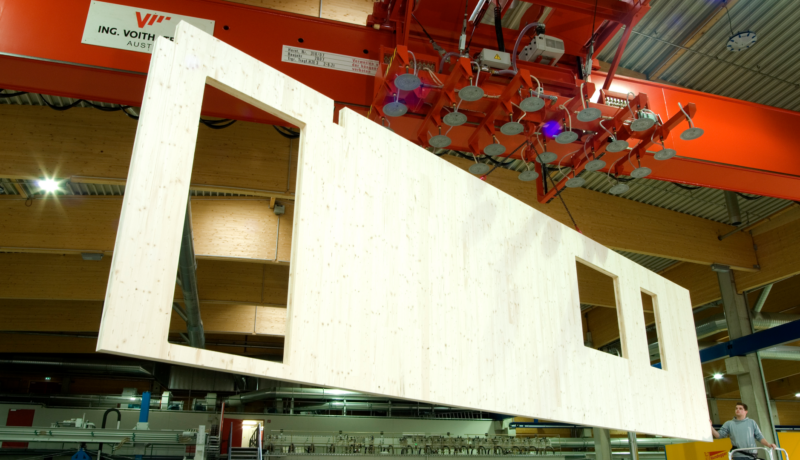

Automated Panel Manufacturing Optimization with Stora Enso

The production process of cross-laminated timber elements, one of Stora Enso’s main massive wood construction products, is defined and constrained by several parameters. Stora Enso also wants to minimize the waste generated…

Learn more