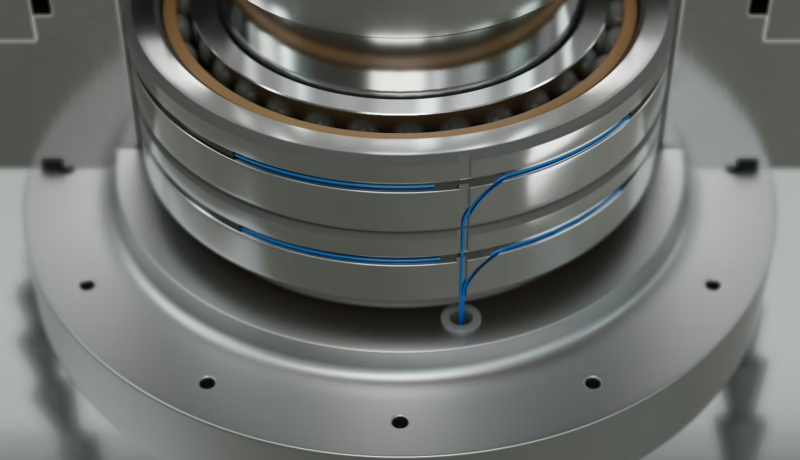

We are seeking a large direct-drive rotation (DDR) solution for wire race bearings in high-end Computer Tomography (CT) systems. By integrating torque motors and control electronics into SKF’s wire race bearing assemblies, we aim to achieve higher rotational stability, lower noise, and smarter condition monitoring with clear potential for long-term series production.

Opportunity overview

High-end CT scanners demand extreme precision, speed, and reliability to deliver superior image quality while maintaining uptime and cost efficiency. Replacing wear-prone transmission components with a direct-drive wire race bearing assembly can deliver a step-change in performance by improving rotational stability and reducing noise. This provides a strong foundation for embedded sensing, data-driven maintenance, and increased equipment longevity in demanding CT environments.

Our vision is to acquire a solution or jointly develop a compact direct-drive subsystem where torque motors are integrated directly into the bearing assembly. We are targeting larger outer diameters of approximately 300–1800 mm. We expect partners to offer more than conceptual designs: functional prototypes suitable for PoC and early testing are required, followed by a clear roadmap from prototype validation to scalable series production for the selected partner.

Summary of the Requested Solution

We are looking for a direct-drive rotation subsystem for high-end CT gantries that combines torque motors, motor control electronics, and other key components integrated into SKF’s wire race bearing products. The solution should deliver high rotational stability, low noise, and long service life, while enabling embedded sensing capabilities for real-time performance monitoring and predictive maintenance.

Your Opportunity with SKF

SKF is the world’s leading bearing manufacturer, with 17,000 distributors in 130 countries. Collaborating with SKF on providing wireless condition monitoring solutions offers an opportunity to contribute to making industries reduce downtime, improving equipment longevity and making industrial operations more resource efficient. We want to work together and provide you with valuable learnings that enable your company further opportunities within the industry.

Examples we're looking for

Direct-Drive Rotation Systems

A flexible direct-drive torque motor solution that can be fully integrated into a SKF wire race bearing assembly optimized for outer diameters of 300–1800 mm and suited to very high-end CT models requiring high precision, speed, and reliability.

Integrated Motor Control and Software Stack

A solution that, in addition to the direct-drive motor, provides motor control electronics and application-specific software, with clear interfaces for integration into SKF’s wire race bearing assemblies and OEM CT systems.

Sensor-Ready Direct-Drive Platform with Embedded Monitoring

A DDR platform designed to host embedded sensors (e.g., vibration, temperature, load) within the bearing and drive system, enabling real-time condition monitoring, reduced unplanned downtime and extended service life for CT gantries.

Cost-Effective FBG Interrogator for Dynamic Sensing with SKF

We are seeking a cost-effective, scalable optical interrogator solution for fiber optic sensor (FOS) bearings, enabling advanced condition monitoring across industrial applications with long-term series production potential. Submission deadline for the opportunity:…

Learn more

Autonomous Workshop Logistics with Scania

Scania is looking for an automated robotic solution to optimize heavy vehicle service workshop logistics and free up technicians’ time for core repair work. The solution should autonomously and safely transport pallets…

Learn more

AI Sales Assistant with Husqvarna Group

We are seeking innovative AI-driven solutions to transform how we support and guide retail sales, with a focus on delivering more personalized, flexible, and effective customer experiences for consumers and small businesses…

Learn more