SKF is a world leader in rolling bearings and related technologies, committed to offering products at the forefront of innovation while supporting clean solutions in the industry. As part of this commitment, SKF seeks to address the drawbacks associated with current methods of transmitting electrical energy to the rotating shaft of Separately/Externally Excited Synchronous Motors used in electric vehicles. The current carbon brush technology faces reliability issues and speed limitations in oil-cooled machines, representing one of the trending developments in the EV market.

Opportunity overview

Separately Excited Synchronous Motor (SESM) technology, while representing less than 5% of the EV market currently, offers substantial advantages in reducing CO2 emissions through using less raw materials. SESMs do not require rare-earth magnets and are thus a more sustainable and reliable motor option.

The key to increasing the adoption of SESMs lies in developing a high-speed and reliable electric connection between the rotating shaft and the power electronics of the motor, eliminating the drawbacks associated with traditional carbon brush sticks. High-speed seals are necessary for the brush to work correctly, and this would increase the cost, risk of failures, and friction, which hinders its broader adoption in the EV market. The proposed solution involves a bearing unit as a stiff, precise rotating element facilitating wireless power transmission from the electronics to the rotating shaft.

A module attached to a bearing or bearing assembly must be developed. SKF can provide bearing units or arrangement, allowing optimal mechanical precision and stiffness to position components close to each other, a crucial feature for an efficient wireless power transfer. The automotive industry is cost-sensitive, so scalability in terms of volume and providing enough value to justify the extra cost of the component are crucial considerations. This innovative solution would align with SKF’s strategy of providing engineered solutions with specific weight, positioning the product as more than just a commodity. Additionally, achieving a better CO2 footprint and reducing dependency on magnet procurement aligns with SKF’s sustainability targets and potential future legislation.

Summary of requested solution

The ideal solution should provide a high-speed and reliable electric connection between the rotating shaft and the power electronics of SESMs. It should eliminate the need for traditional carbon brushsticks, resulting in a more dependable and potentially cost-effective solution at the system level. The answer could enable wireless power transmission more reliably and efficiently by utilizing technologies such as inductive or capacitive power transfer and other out-of-the-box concepts such as conductive fluids. This wireless power transmission bearing unit, that is, one or several bearings in a specific arrangement, should be designed to be easily integrated into SESMs without compromising the size of the system. It should be capable of withstanding the demanding conditions of EV applications, and the solution should deliver seamless energy transfer, ensuring optimal performance and efficiency of the SESM throughout its operational lifespan.

Your opportunity with SKF

SKF is the world’s largest bearing manufacturer, with 17,000 distributors in 129 countries. SKF has been a pioneer and is today one of the leaders in providing bearing solutions for EV Powertrains. As sustainability becomes increasingly critical for the automotive industry, the potential partnership presents an opportunity to contribute to a greener future while expanding your company’s market presence and industry knowledge. By revolutionizing rotation for EVs and supporting SKF’s clean solutions strategy, your company can shape the future of electric mobility while benefiting from the growth opportunities it presents.

Examples we're looking for

Inductive & Capacitive Power Transfer

Inductive or capacitive technology that will enable the wireless power transmission between the rotating shaft and the power electronics of the motor can be the key to replacing the current carbon-based system. The solution would utilize the benefits of the bearing features, such as mechanical accuracy and stiffness.

Conductive Fluids

A less conventional approach could be using fluids with high electrical conductivity that can facilitate the transmission of electrical energy wirelessly, which has potential applications in various fields, such as in powering the bearing units in connection to SESMs in EVs.

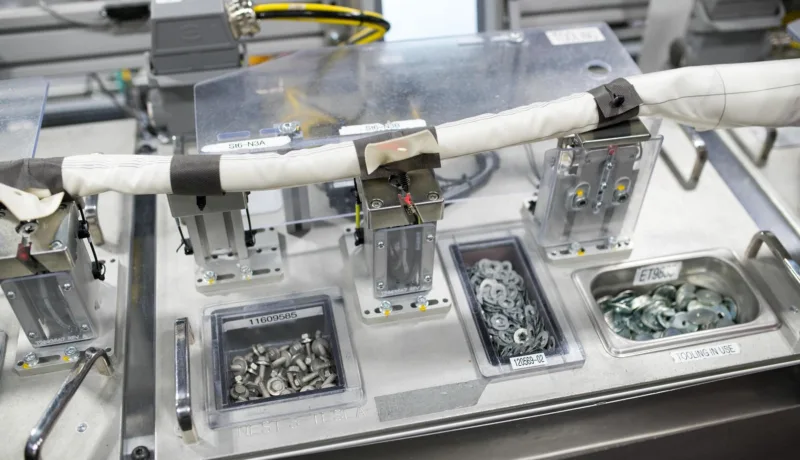

Automatic Taping with Autoliv

Autoliv is the world’s largest automotive safety supplier, specializing in designing and manufacturing safety systems like airbags and seatbelts for the automotive industry. In this opportunity, Autoliv focuses on inflatable curtain airbags…

Learn more

Remanufacturing Return Flow Platform with SKF

SKF is a world leader in rolling bearings and related technologies. As a prominent industrial player, their work towards more sustainable operations and limiting the negative environmental impact is constant and ambitious.…

Learn more

Optimizing Grinding Efficiency through Torque Analysis with SKF

SKF is a world leader in rolling bearings and related technologies. As a prominent industrial player, the work towards improving manufacturing processes is constant and ambitious. Now, SKF is looking for solutions…

Learn more