Munters is on the lookout for novel or existing materials that can serve as substitutes for copper piping in low-pressure refrigeration systems for data center cooling to keep up with evolving industry needs.

Opportunity overview

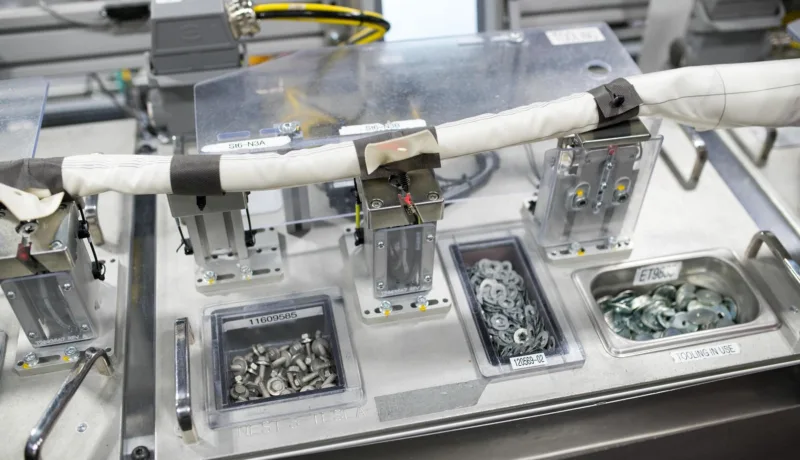

Munters provides data centers with efficient cooling technology based on a thermosiphon cooling loop system. This solution cools data centers without requiring refrigerant pumps or compressors for a substantial duration each year. However, using copper pipes to connect the condenser and evaporator poses challenges due to their high cost as a material and the installation process involved. With the rapid growth of data centers, finding ways to improve operational efficiency and prevent pipe installation from becoming a bottleneck is crucial.

Copper has long been the standard piping material for refrigeration and air conditioning systems. It offers several advantages, including excellent strength and pressure limits, a well-established supply chain, zero permeability of refrigerants, and tolerance to lubricant oil. Furthermore, copper is 100% recyclable, making it an environmentally friendly choice. However, copper pipes must be welded or brazed together during installation, requiring a high skill level to ensure proper connections and system integrity. Adding this to the high cost of materials significantly impacts project budgets.

Now, we are looking for piping systems with lower product costs and easier installation than copper pipes. The system must operate up to a maximum working pressure of 20 bar, have an operational temperature of -40 to 65 degrees Celsius, and be suitable for refrigerants such as HFCs and HFOs. The initially required sizes are 2-1/8″ OD and 4-1/8″ OD. It should seamlessly transition to equivalent-sized copper pipes using a Victaulic coupling or other suitable means. Solutions for 90-degree and 45-degree elbows are needed, and the system should weigh less than equivalent-sized copper tubing. Also, it should be ideal for both exterior and interior installations.

Your opportunity with Munters

Munters seeks a partner to join forces in developing a product that addresses this growing market need. The collaboration holds the potential for a co-development partnership, enabling the partner to scale alongside Munters’ expanding business while gaining direct access to its extensive customer base. This cooperative effort can evolve into a licensing agreement in the long term, leveraging Munters’ well-established sales channels to drive substantial business growth and achieve broader market penetration.

Examples we're looking for

Material science

The piping system can incorporate innovative materials with improved properties, such as a higher strength-to-weight ratio, enhanced corrosion resistance, and increased flexibility compared to copper.

Material coating

These coatings can protect against environmental factors, chemicals, and moisture, ensuring the system’s integrity and reducing maintenance needs.

Operational efficiency

Optimizing the design and configuration of the piping system can improve its operational efficiency. This includes streamlined flow paths, alternative coupling, reduced pressure drops, and minimized heat transfer losses.

Automatic Taping with Autoliv

Autoliv is the world’s largest automotive safety supplier, specializing in designing and manufacturing safety systems like airbags and seatbelts for the automotive industry. In this opportunity, Autoliv focuses on inflatable curtain airbags…

Learn more

Remanufacturing Return Flow Platform with SKF

SKF is a world leader in rolling bearings and related technologies. As a prominent industrial player, their work towards more sustainable operations and limiting the negative environmental impact is constant and ambitious.…

Learn more

Optimizing Grinding Efficiency through Torque Analysis with SKF

SKF is a world leader in rolling bearings and related technologies. As a prominent industrial player, the work towards improving manufacturing processes is constant and ambitious. Now, SKF is looking for solutions…

Learn more