Husqvarna Group is looking for next‑generation battery cells that combine high energy density, high power capability and improved safety to power our most demanding products. The right solutions will extend runtime and power output while enabling simpler, more cost‑efficient battery systems for high‑power outdoor and off‑road equipment.

Opportunity overview

Today’s battery technologies often force trade‑offs between runtime, peak power and safety, especially in compact, high‑power tools and machines. At the same time, electrification, sustainability targets and tightening regulations are accelerating the shift from combustion engines to battery solutions in professional outdoor and construction applications. Husqvarna Group wants to address these constraints by adopting cell technologies that improve performance and safety, while keeping systems robust and cost‑efficient in demanding real‑world use.

We are seeking startups and scale‑ups that can provide or co‑develop battery cells and closely related technologies that match our performance profiles. We are particularly interested in partners with an industrialization and supply footprint in Europe and/or the US, and in solutions that are relevant for high‑power and outdoor power equipment applications.

Your Opportunity with Husqvarna

By collaborating with Husqvarna Group, startups gain access to real‑world, high‑power applications and the opportunity to validate and refine their technology against our constraints. Selected companies will receive technical collaboration with our battery R&D and application teams, and benefit from structured feedback on performance, safety and scalability.

Successful pilots can form the basis for long‑term supply relationships, where the startup provides cells and Husqvarna Group integrates them into industrialized battery packs across multiple product platforms.

Examples we're looking for

High‑energy and high‑power cells

Battery cells that deliver both high energy density and high power capability over demanding duty cycles, suitable for products with sustained high power draw. This includes chemistries and designs that enable longer runtime without sacrificing peak power performance. The below specifications give good indication of the measurements we are after in long-term:

- Gravimetric energy density above 400 Wh/kg

- Cell size between 2 and 15 Ah

- Preferably in cylindrical 21700 format but pouch format can also be relevant

- Power density of at least 2500 W/kg

- Intermediate number of cycles

Novel battery chemistries and EU/USA based LFP

Advanced solid‑state, sodium‑ion or other emerging chemistries with a credible roadmap toward higher energy and power performance and improved safety for high‑power outdoor applications.

Support for high-power operation, robust safety, and attractive cost are the key attributes we are seeking. Additionally, we are interested in LFP battery cells manufactured in the EU or USA.

AI Customer Persona Agents with TRATON

Within our partnership framework, TRATON Group—consisting of the leading commercial vehicle brands Scania, MAN, International, and Volkswagen Truck & Bus—is seeking an AI-driven solution that gives TRATON Group R&D teams fast and realistic…

Learn more

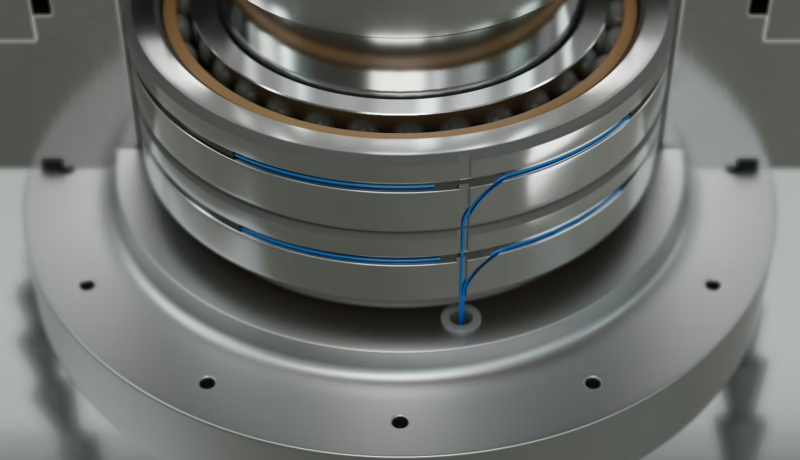

Direct Drive of Wire Race Bearing in Computer Tomography with SKF

We are seeking a large direct-drive rotation (DDR) solution for wire race bearings in high-end Computer Tomography (CT) systems. By integrating torque motors and control electronics into SKF’s wire race bearing assemblies,…

Learn more

Cost-Effective FBG Interrogator for Dynamic Sensing with SKF

We are seeking a cost-effective, scalable optical interrogator solution for fiber optic sensor (FOS) bearings, enabling advanced condition monitoring across industrial applications with long-term series production potential. Submission deadline for the opportunity:…

Learn more