Husqvarna Group looks to shift high‑value diamond tool consumables into data‑enabled assets. With smart consumables, we aim to help contractors track usage, reduce stockouts of consumables, optimize inventory, and plan projects more efficiently.

Opportunity overview

Contractors rely on diamond cores drill and blades for drilling and sawing, yet today they have low visibility into how, where, and how intensively these tools are used. Consumables can go missing between sites, wear out unexpectedly, or are simply not available where and when needed, leading to lost time and higher costs. At the same time, construction projects are becoming more data‑driven, with increasing pressure on productivity, traceability, and sustainability. Husqvarna Group wants to address these challenges by turning consumables into intelligent, connected assets.

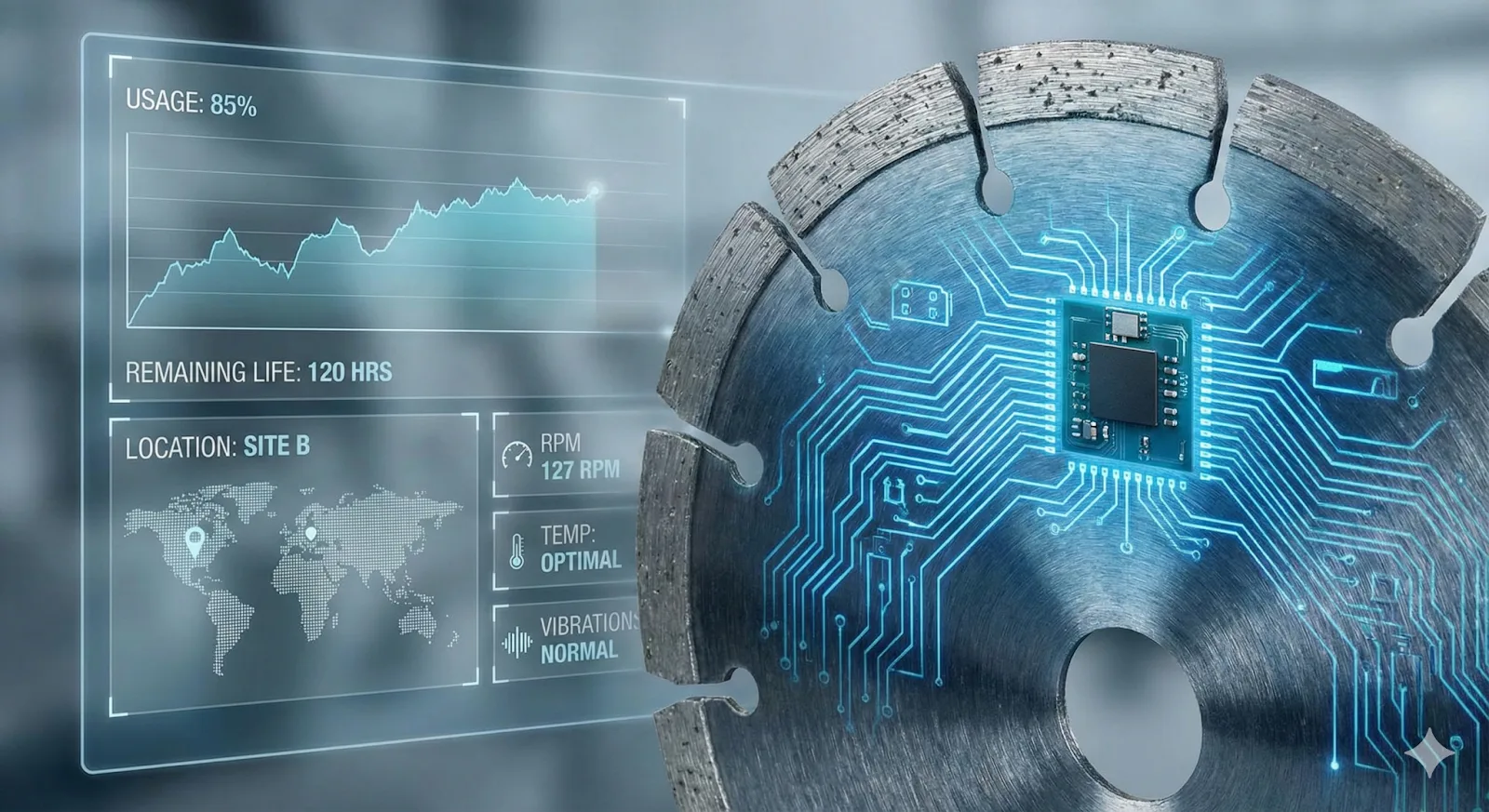

We see an opportunity to build an end‑to‑end solution that brings intelligence to diamond tools and turns usage data into actionable insights for contractors. Today, these challenges are handled with manual tracking, experience‑based estimation, and fragmented digital tools. Instead of prescribing a single technical architecture, our vision is a flexible connected system where each tool and drill motor can be uniquely identified (e.g. via NFC, QR, RFID, or similar), and where smart, reusable sensing and communication solutions associated with tools and/or machines capture relevant data (e.g. RPM, load/usage profile, operating time, location). Data should be able to flow via suitable means to the cloud and into Husqvarna Group’s existing digital ecosystem.

Startups should be able to contribute key capabilities in smart hardware, data capture and connectivity, and/or software and analytics that solve these concrete use cases, with openness to different sensing locations (on‑tool, on‑machine, in‑line, etc.) and protocol choices, while remaining compatible with different possible hardware architectures and connectivity approaches.

Your Opportunity with Husqvarna

For startups, this is an opportunity to co‑create and scale a new category of connected consumables together with a global industry leader. A successful solution can be replicated across multiple tool types, applications, and markets, enabling recurring revenue models around hardware, data, and digital services. Husqvarna Group brings deep domain expertise in diamond tools, drilling, and sawing, access to real end users and demanding field environments for pilots, an established digital ecosystem to integrate with, and industrialization and global go‑to‑market capabilities.

Examples we're looking for

Smart, reusable hardware for consumables

Compact, rugged sensing and communication modules that can be mounted on rotating diamond tools, read product IDs, measure RPM and optionally current, and operate reliably in dust, vibration, and harsh jobsite conditions.

Data capture, connectivity and power management

Flexible ways to move data from the tool to the cloud (e.g. Bluetooth, smartphone apps, edge gateway/smart box, cellular, or other suitable industrial connectivity), combined with smart power concepts (e.g. low‑power design, inductive charging, energy‑efficient duty cycling) and, where feasible, GPS/location capabilities for asset tracking.

Software, interfaces and integration

Design and development of the software and user interfaces that translate raw data into value for contractors, such as:

- Tool usage visibility and analytics

- Inventory planning and replenishment support

- Asset tracking and utilization

- Project documentation and reporting

AI Customer Persona Agents with TRATON

Within our partnership framework, TRATON Group—consisting of the leading commercial vehicle brands Scania, MAN, International, and Volkswagen Truck & Bus—is seeking an AI-driven solution that gives TRATON Group R&D teams fast and realistic…

Learn more

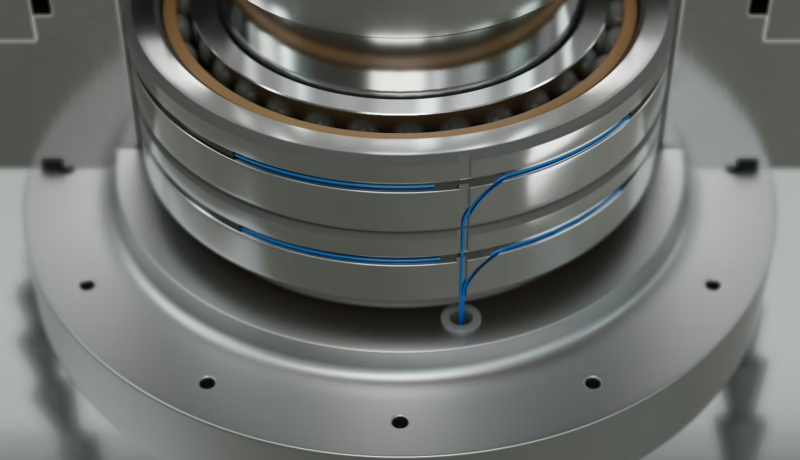

Direct Drive of Wire Race Bearing in Computer Tomography with SKF

We are seeking a large direct-drive rotation (DDR) solution for wire race bearings in high-end Computer Tomography (CT) systems. By integrating torque motors and control electronics into SKF’s wire race bearing assemblies,…

Learn more

Cost-Effective FBG Interrogator for Dynamic Sensing with SKF

We are seeking a cost-effective, scalable optical interrogator solution for fiber optic sensor (FOS) bearings, enabling advanced condition monitoring across industrial applications with long-term series production potential. Submission deadline for the opportunity:…

Learn more