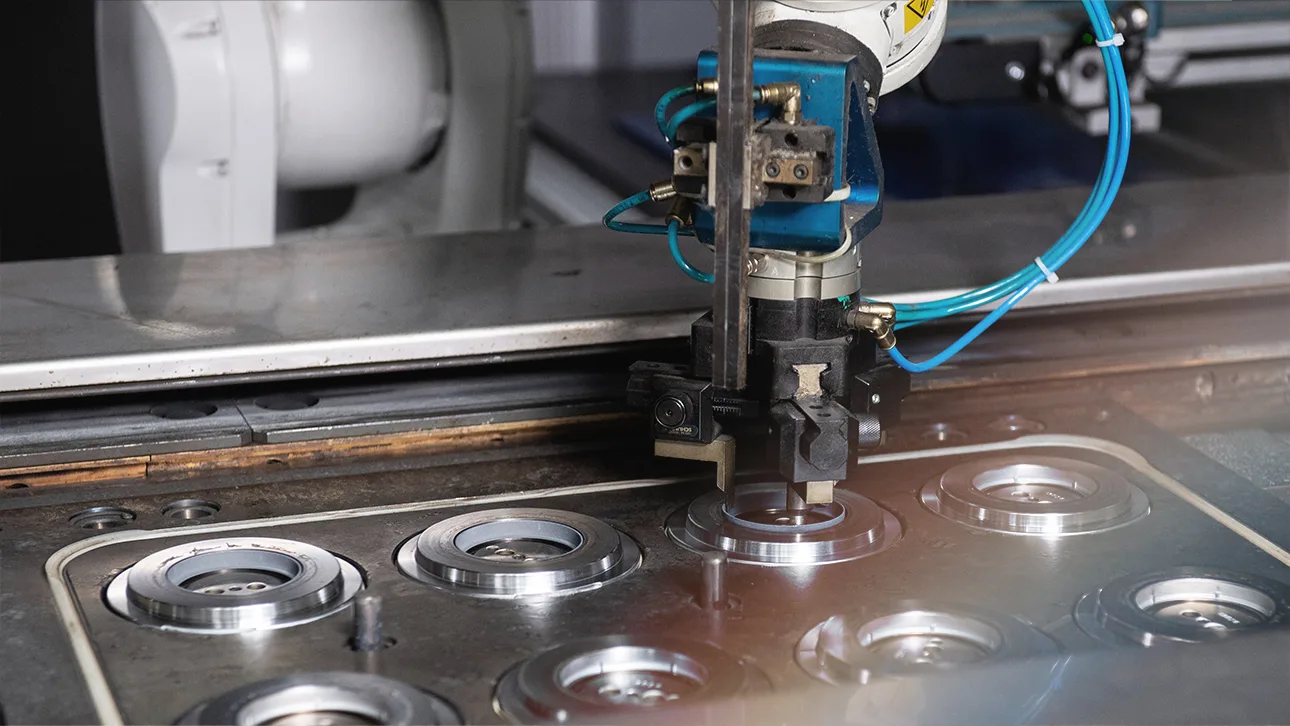

SKF is a world leader in rolling bearings and related technologies, constantly looking to optimize manufacturing processes. In the production of seals, a crucial step involves bonding a metallic insert and rubber. During the molding process, certain amount of rubber needs to become waste due to the way rubber flows inside the mold. Besides, some defects in the molded parts can also occur already during production, rendering the whole product unusable. The potential reuse of both the rubber and the pre-treated metallic inserts is complex and consequently, the entire product is often discarded. Now, we are looking for solutions to improve the reusability of the parts through efficient recycling methods and ways to separate the materials.

Opportunity overview

The reuse of rubber is complex due to its production chemistry, while reusing the metallic inserts after the pre-treatment process is impractical. This often leads to discarding the entire defect product even when the metallic insert still has value, leading to both economic and environmental inefficiency. The solution should be a process to de-bond or separate the molded rubber from the metallic insert, enabling the reuse of the insert without affecting its physical properties. Regarding the rubber compound, a technology that enables the reuse of the rubber scrap generated in different stages of the process is also under exploration. Solving the challenges would considerably reduce the amount of valuable materials going to scrap and the CO2 footprint. The circularity of the production process would be elevated, catering to the demands of the environment and customers.

Summary of the requested solution

The solution should address the separation of the moulded rubber from the metallic insert in defect parts during seal production, minimizing valuable materials going to scrap. Additionally, a technology facilitating the reuse of rubber attached, or not, to the insert is also of interest. The solution must consider the initial treatment of the insert and enable retreatment, allowing the insert to be reused in the production line. The solution would ultimately be implemented in SKFs internal seals production sites.

Your opportunity with SKF

SKF is the world’s largest bearing manufacturer, with 17,000 distributors in 130 countries. As a leader in our field, we can offer you a significant reference for your solution and a chance to make a real impact at a large scale. Collaborating with SKF on developing a solution to reuse materials from defect products allows your solution to contribute to a reduction in the Co2 footprint and an improvement in the circularity of the production process. We want to work together and provide you with valuable learnings from the manufacturing space, enabling your company further opportunities within the industry.

Examples we're looking for

Debonding technologies

Novel solutions for debonding or separating moulded rubber from metallic inserts, enabling the reuse of the metallic parts without compromising their physical properties are under exploration.

Rubber recycling

Innovative technologies facilitating the recycling of the rubber scrap generated throughout the process are also of interest, enabling the rubber reuse in the production line and reducing scrap.

New Barrier Materials and Coating Methods with Stora Enso

Stora Enso, a leader in renewable materials, is looking to broaden its range of coating solutions and surface treatment technologies that could be applied to our packaging. We are developing new generations…

Learn more

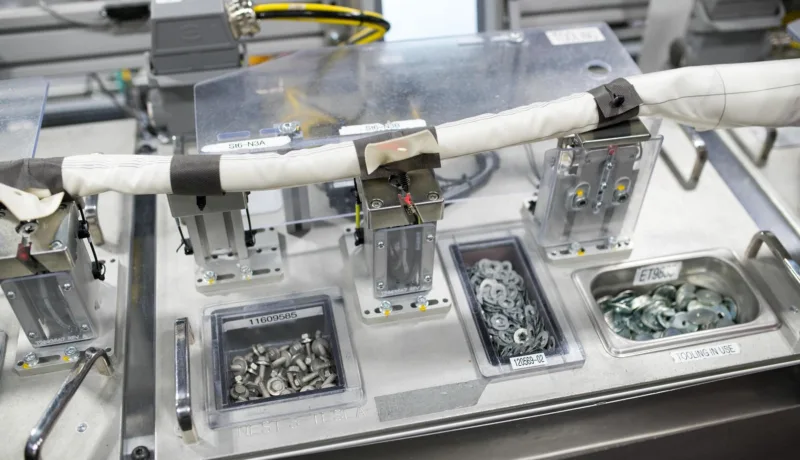

Automatic Taping with Autoliv

Autoliv is the world’s largest automotive safety supplier, specializing in designing and manufacturing safety systems like airbags and seatbelts for the automotive industry. In this opportunity, Autoliv focuses on inflatable curtain airbags…

Learn more

Water Recycling System for Sustainable Drilling with Epiroc

Epiroc is vital to a sustainable society and a global productivity partner for mining and infrastructure customers. As a pioneer in innovative drilling solutions, Epiroc is dedicated to advancing sustainable practices within…

Learn more