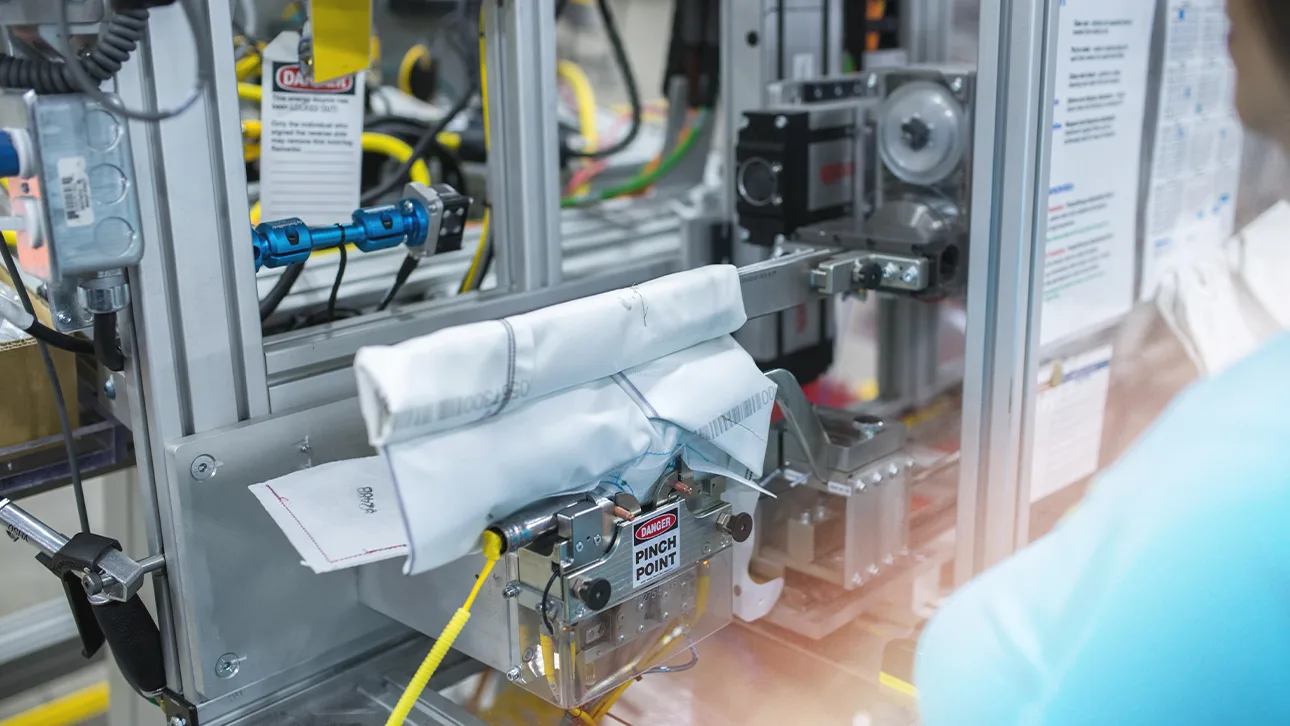

Autoliv is the world’s largest supplier of automotive safety solutions, operating across 27 countries with 14 tech centers globally. It is known for designing, developing and manufacturing cutting-edge safety systems for the automotive industry and mobility safety solutions. Autoliv’s vision of ”Saving More Lives” drives the efforts of its 70,000 dedicated employees, fueled by a passion for innovation and collaboration. Now, we are seeking a supplier or developer capable of providing a novel solution for closing the folded cushion of an airbag. The aim is to reduce the need for fabric and manual operators at the closing station. The manual folding process currently involves utilizing a wrapper and mounting pins to secure the cushion in place.

Opportunity overview

Autoliv plays a critical role in protecting and saving lives on a daily basis, making quality their top priority. As a result, Autoliv places high demands on precision and ensures the production of well-crafted products. Through this business opportunity, we aim to take the airbag closure methods and technologies to the next level. The primary goal is to identify a developer capable of replacing the fabric wrappers currently used in the production. The key challenge lies in the current stapling machine used for airbag closure, equipped with a thin needle that proves too fragile for several cycles. It is crucial to find an innovative airbag enclosing solution with e.g. a needle or staple that can effectively handle multiple layers of fabric without breaking itself or the fabric Implementing a new automated, robust, and effective solution holds the potential to significantly reduce material and labor costs as well as cycle times for Autoliv.

Your opportunity with Autoliv

Working with Autoliv offers a chance to partner up with a world-leading provider of automotive safety systems and engage in a strategically important field.

A successful solution could be implemented across airbag production lines globally, extending beyond side-airbags to include all types of airbags produced. Although Autoliv is actively seeking a ready product to be implemented, we remain open to co-development proposals from potential suppliers.

Examples we're looking for

Airbag closure

The solution needs to autonomously manage the closure of an airbag. The result should be robust enough to keep the side airbag securely closed, yet capable of deploying swiftly in case of an emergency.

Robustness

An alternative robust solution designed to essentially maintain constant in countless cycles. The tagging solution must not only withstand many cycles but also refrain from cutting airbag fibers beyond acceptable limits.

Cost-effective

The solution should minimize the material costs by reducing the need for fabric wrappers. Additionally, it should be able to go through multiple layers of fabric, up to ~30 layers.

New Barrier Materials and Coating Methods with Stora Enso

Stora Enso, a leader in renewable materials, is looking to broaden its range of coating solutions and surface treatment technologies that could be applied to our packaging. We are developing new generations…

Learn more

Water Recycling System for Sustainable Drilling with Epiroc

Epiroc is vital to a sustainable society and a global productivity partner for mining and infrastructure customers. As a pioneer in innovative drilling solutions, Epiroc is dedicated to advancing sustainable practices within…

Learn more

Orebody Knowledge for Sustainable Mining with Epiroc

Epiroc is vital to a sustainable society and a global productivity partner for mining and infrastructure customers. As a leading provider of innovative mining equipment, technology, and services, Epiroc is dedicated to…

Learn more