Autoliv is the world’s leading manufacturer of automotive protective systems for all the major automotive OEMs. Autoliv is committed to operating its business at the highest level of quality and at the most efficient cost possible. Autoliv fabrics are used in automotive safety applications such as airbags, steering wheels and seats. Currently, unloading flat fabric components after laser cutting from a conveyor belt is a highly manual process which requires up to 6 operators per shift. A successful pick & place solution can be deployed to unload fabric components increasing operator safety, reducing material costs and decreasing the amount of manual labor required.

Opportunity overview

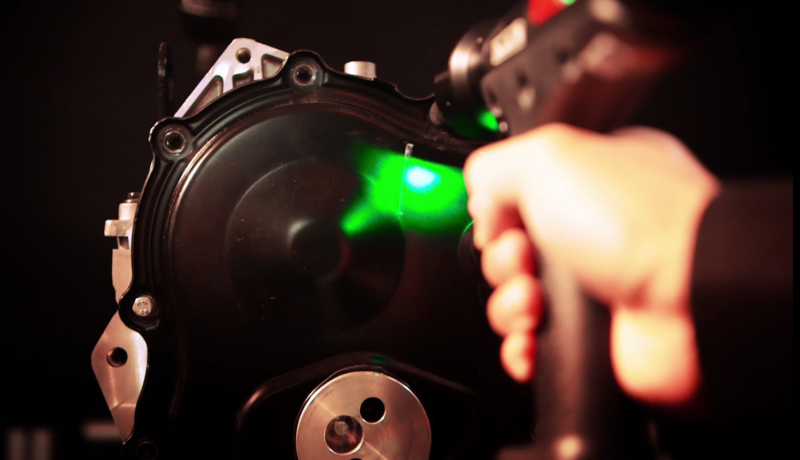

Automating the pick & place flow of fabric components has many application areas in car safety equipment manufacturing, which can improve productivity and safety. The process starts with a nesting solution that fits customer-specific components onto fabric, minimizing residue. A laser cutter cuts the desired components out of the fabric. After laser cutting, human operators carry out manual tasks such as visual inspection as well as positioning and packaging cut fabric components to loading boxes. The pieces of fabric can contain quality defects such as incomplete or additional cuts, issues with the fabric or other markers, which require manual inspection and intervention by the operator. An ideal solution should be flexible, scalable and capable of picking and positioning deforming fabric components with varying thickness and texture. The solution should also enable the fallback to using operators under special circumstances.

Your opportunity with Autoliv

Autoliv is the leading manufacturer of automotive safety products. Laser cutting is the beginning of the textile process in every Autoliv textile plant. A successful implementation will have a fast payback mainly from:

1) reducing labor costs,

2) reducing injuries at unloading areas, and

3) saving fabric material. Autoliv plans to roll out the solution to 12 sites and has committed resources, including a team and a budget. A successful solution can be further scaled to wide internal use e.g. to multiple production facilities.

Examples we're looking for

EFFICIENCY

The autonomous solution should be able to unload components of various shapes and sizes without slowing down the laser cutting process.

VISUAL QUALITY CONTROL

An ideal solution should be able to carry out the quality inspection tasks done by the operator. Not OK parts should be rejected and registered to the system. The solution should enable Autoliv to save material costs by reducing fabric waste.

FLEXIBLE UNLOADING

The pick and place solution should be applicable to different types of fabric components and laser unloading areas. It should also enable manual unloading by operators under special circumstances.”

Green Space Index for Residentials with Husqvarna Group

We want to inspire actions that makes a lasting difference and improve quality of life. A key area for Husqvarna Group is gardening, and our purpose is to provide products and services…

Learn more

Measuring Sustainable Behavioral Change with Husqvarna Group

We have an ambition to inspire actions that makes a lasting difference. By 2025, our goal is to empower 5 million customers and colleagues to make sustainable choices. We are now searching…

Learn more

Real-time Visual Quality Control with Atlas Copco Desoutter

At Desoutter, part of Atlas Copco group, we design, manufacture and sell innovative solutions – both tools and software – for assembly and process control in the motor vehicle, aerospace, and general…

Learn more