Atlas Copco Bolting Solutions is a part of our Industrial Technique business area. We are a leading provider of bolt-tightening solutions for the wind energy sector and others. With this opportunity, we aim to connect our bolt-tightening tools in the field to help improve quality and productivity in the wind industry.

Opportunity overview

The global wind energy market is a highly competitive business with a strong outlook for growth. However, cost pressure and regulatory requirements drive the industry to work smarter. As major OEMs publicly state in their annual reports, inadequate quality control is a crucial obstacle to unlocking profitability and productivity.

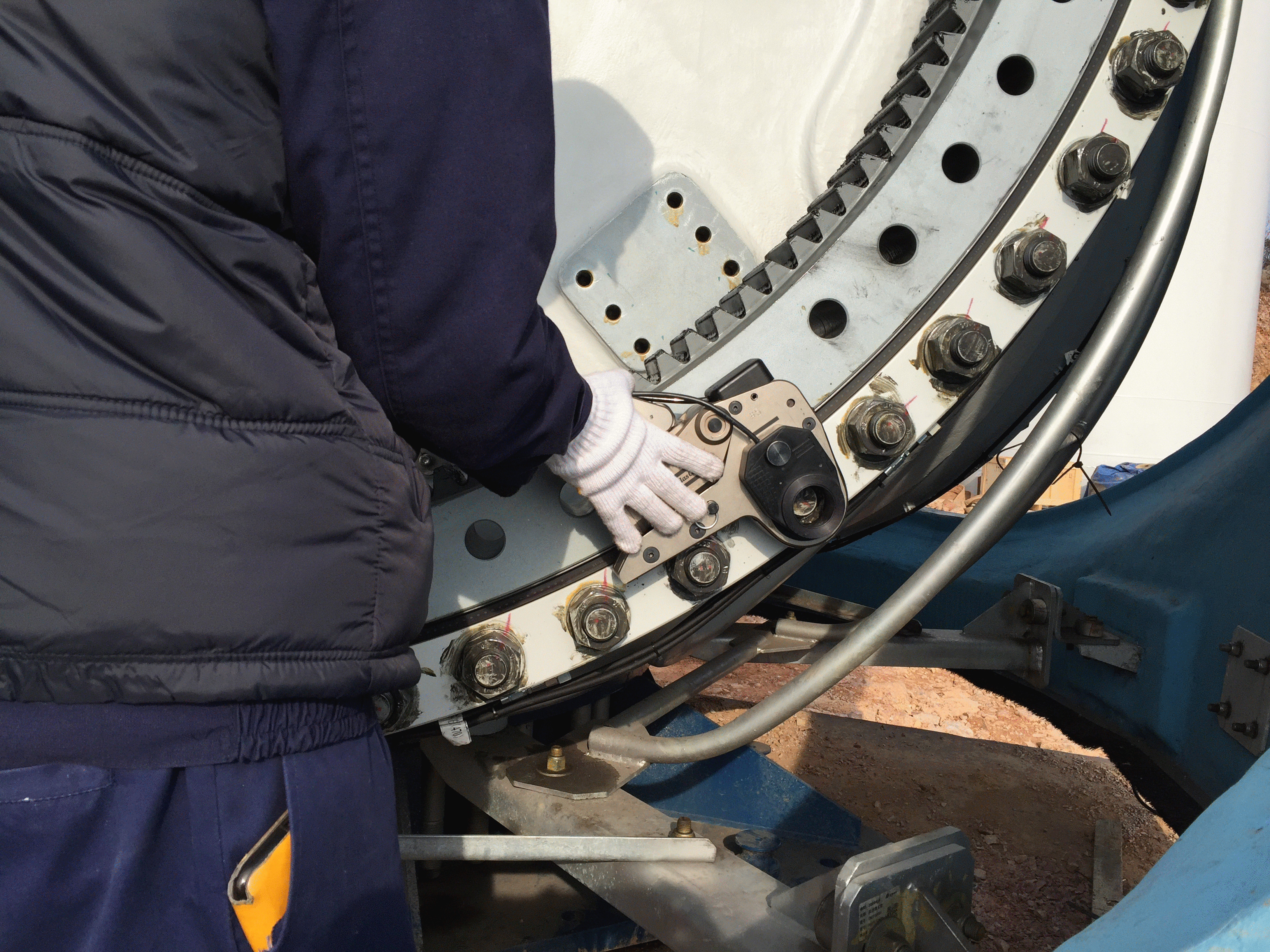

Tightening bolts is a critical part of the quality process in wind turbine construction and maintenance. Today, state-of-the-art assembly plants have a fully digitalized assembly process. The conditions off-shore and even on-shore are vastly different, and the work environment is rough. In the field, the quality control and documentation process is still manually handled using pen and paper. Consequently, data transparency and integrity are critical challenges for the industry.

This is now changing, with innovative tools entering the field. These tools control the process and produce a digital record of the job done. We are searching for partners with industry experience to jointly develop a solution for remote bolt-tightening data collection.

We envision a solution where tightening data is collected from the tools and uploaded seamlessly to a cloud database. The Wi-Fi and Bluetooth connectivity built into the tools can be used for data extraction and linked to the cloud via mobile devices when connectivity is available. A desired solution should also work with limited connection and be compatible with various wind turbine models and bolting tools.

Your opportunity with Atlas Copco

Atlas Copco has 150 years of proven track record of transformational innovation and making substantial R&D investments to remain relevant to our customers. With this opportunity, you will join us in accelerating the green energy transformation and benefitting from the vast business opportunity associated with it.

As a partner, you will work with our R&D teams and get access to our global customer center network. As bolt tightening is a critical process in the construction and maintenance of wind turbines, we believe the value of the tightening data strongly supports the value proposition of a data platform. We are open to various collaboration models spanning from turnkey solutions to co-creation.

Examples we're looking for

Data collection

An ideal solution would be to collect data securely from the tightening tools.

Data transfer

An ideal solution would be to transfer the collected data in varying connectivity conditions.

Data visualization and management

An ideal solution would help stakeholders in the wind industry to make data-driven decisions in turbine assembly and maintenance.

Real-Time 3D Screening with Autoliv

Autoliv is the world’s leading manufacturer of automotive protective systems for all the major automotive OEMs. We are committed to operating our business at the highest quality and the most efficient cost…

Learn more

Sustainable Polymers with Autoliv

Autoliv is the world’s leading manufacturer of automotive protective systems for all major automotive OEMs. We use various polymers in automotive safety applications, such as airbags, steering wheels, and seats. As the…

Learn more

Sustainable Reusable Food Packaging with Stora Enso

We want to co-develop sustainable material solutions for reusable food packaging

Learn more