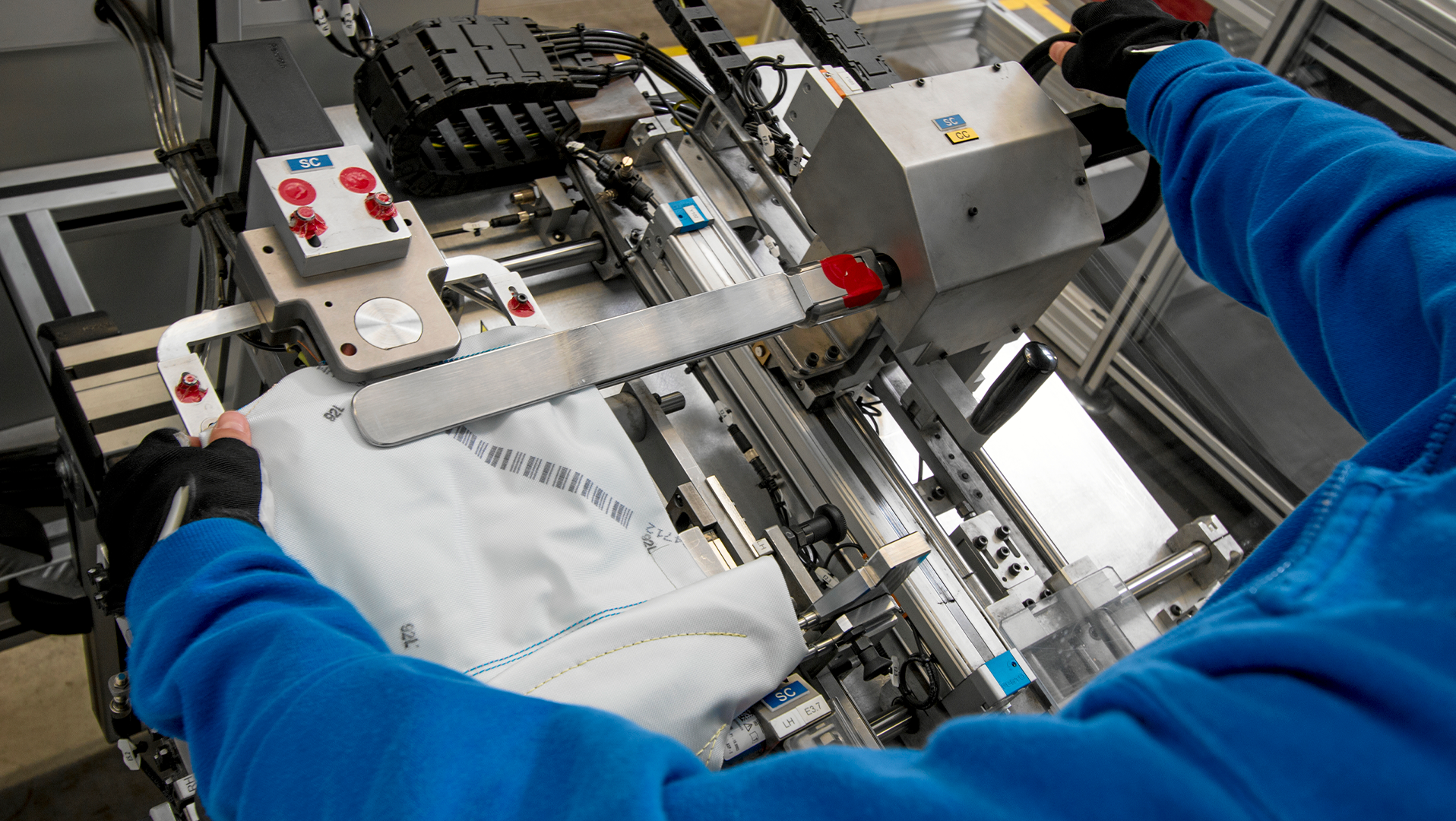

At Autoliv, we are guided by our vision of Saving More Lives. To this aim, we are dedicated to delivering products of the highest quality and competitive cost while also focusing on increasing resource efficiency and reducing our carbon footprint. We aim to limit our environmental impact by reducing water consumption, waste generation, and CO2 emissions. We are looking to identify solutions and technologies to monitor and optimize energy consumption at plant, line, and machine levels, possibly across several of our product lines, to drive down energy use and associated costs. What solutions and technologies do you have to offer in this space?

Opportunity overview

We are committed to operating our business in an environmentally sustainable manner and developing and producing products energy-efficiently while preventing pollution and limiting our environmental impact. We are constantly trying to reduce waste, energy consumption, CO2e emissions, and water usage at our facilities.

Reducing the environmental impact of Autoliv’s industrial activities is also a matter of focus to ensure long-term business. We are facing increasing energy costs, and thus, we see great potential in improving our capabilities to monitor and reduce our energy consumption across several of our product lines at plant, production line, and machine levels. Real-time visibility and intelligent control of our energy consumption could help us decrease product costs, stay competitive, and efficiently use the planet’s resources.

Based on our observations, several technologies are available today to monitor energy consumption. In addition, intelligent solutions to track and optimize facilities, machine conditions, and energy usage in real-time have become more accessible. These new solutions are opportunities to maximize energy utilization at Autoliv facilities further, and we’d like to hear from innovative solution providers in this field.

Your opportunity with Autoliv

We aim to pilot and implement automatic, accurate time energy consumption monitoring and optimization systems. To achieve this, we invite the most talented startup teams and growing technology companies to work with us on some of the most significant industrial opportunities in energy saving.

We believe that all of our energy consumption can be tracked and optimized. According to our vision, an optimal solution would enable our skilled operators working at production lines and facilities to receive accurate feedback on normal and abnormal energy consumption conditions and help them make better decisions in real-time.

We envision an energy optimization system that crunches different sensory data inputs, learns from possible patterns in the data, and can provide real-time feedback to the operators. Ideally, The plan would include several energy consumption data inputs such as electricity usage, compressed air, gas, water, and other possible information. The gathering and analysis of the data should be granular enough to identify abnormalities and suggest preventive actions to be taken. The system should be able to display the data in an understandable dashboard for real-time- and historical data analysis. About gathering various data inputs, we are looking for plug-and-play hardware components that could be implemented in a cost-efficient manner.

Below you can read more on some elements of the solution we envision to have for such systems. If you think you have a solution that could be of value to us in one or several of these elements, don’t hesitate to contact us!

Examples we're looking for

Plug-and-play energy measurement sensors

We are looking for a monitoring system, starting with plug & play, wireless, non-intrusive sensors that could gather data about the electricity consumption of our production equipment, machines, and facilities. Easy installation and cost-effectiveness are essential factors in our selection of sensors. We’d like to hear from your sensor solutions!

Energy consumption analytics software

To use the energy consumption data gathered from sensors installed in our facilities, we are keen to learn about software solutions that could provide quick insights on possible deviations and suggest corrective actions in real time. This could potentially enable significant cost reduction and even more sustainable manufacturing. What would you have to offer for this opportunity?

Adaptive pattern recognition algorithms

Our purpose for this monitoring initiative is to learn about possible energy consumption deviations and patterns to optimize consumption in the long term. We have identified potential in intelligent, adaptive algorithms to do a large part of this almost automatically and would like to explore solutions that enable that in our context. Could your pattern recognition algorithm help us?

Circularity Co-Creation with Stora Enso

Many of Stora Enso’s customers have defined sustainability targets but find it difficult to understand how improvements in packaging development, design, and material choices impact achieving these targets. We want to develop…

Learn more

Product Authenticity with Stora Enso

Stora Enso, a leader in renewable packaging, wants to support its e-commerce and retail customers by preventing counterfeit and tampering with the help of innovative packaging solutions. Retail brands have a strong…

Learn more

Low-Carbon Circular Materials by KONE

KONE, a global elevator and escalator industry leader, has set science-based targets for significant reductions in its greenhouse gas (GHG) emissions by the year 2030. In addition, KONE has pledged to have…

Learn more