At Desoutter, part of Atlas Copco group, we design, manufacture and sell innovative solutions – both tools and software – for assembly and process control in the motor vehicle, aerospace, and general industry markets. As a global leader in our markets, we wish to expand our portfolio further with additional measurement equipment and in-line control software for visual quality control.

Opportunity overview

Our customers want to optimize their industrial setup with innovative solutions designed for the purpose of improving productivity, flexibility and uptime. We already provide solutions for process control, and tightening, but we see further added value and significant potential in integrating more quality measures into our offering.

We are looking for partners that could help us increase our portfolio in equipment capable of measuring specific product characteristics, and software for analyzing results in real time to suggest solutions or real-time corrections. Our initial focus is dimensional control and component presence using automated vision system combined with smart analytics software. Furthermore, we are looking for partners with a dynamic design team, and existing solutions whose efficiency and robustness have been demonstrated already.

Your opportunity with Atlas Copco Desoutter

As a global company, with a long history and established reputation for high-end solutions in our markets, we can sell to well known customers and provide access to a wide range of regions with significant potential in further extending to new markets.

We are looking for an R&D partner with a dynamic design team, and potentially a dedicated manufacturing site for our in-line quality solutions. You will have access to our domain expertise and resources. We have an industry-leading R&D team with over 200 people experienced in working with startups and scaleups to improve and integrate solutions while simultaneously keeping the required level of differentiation.

Examples we're looking for

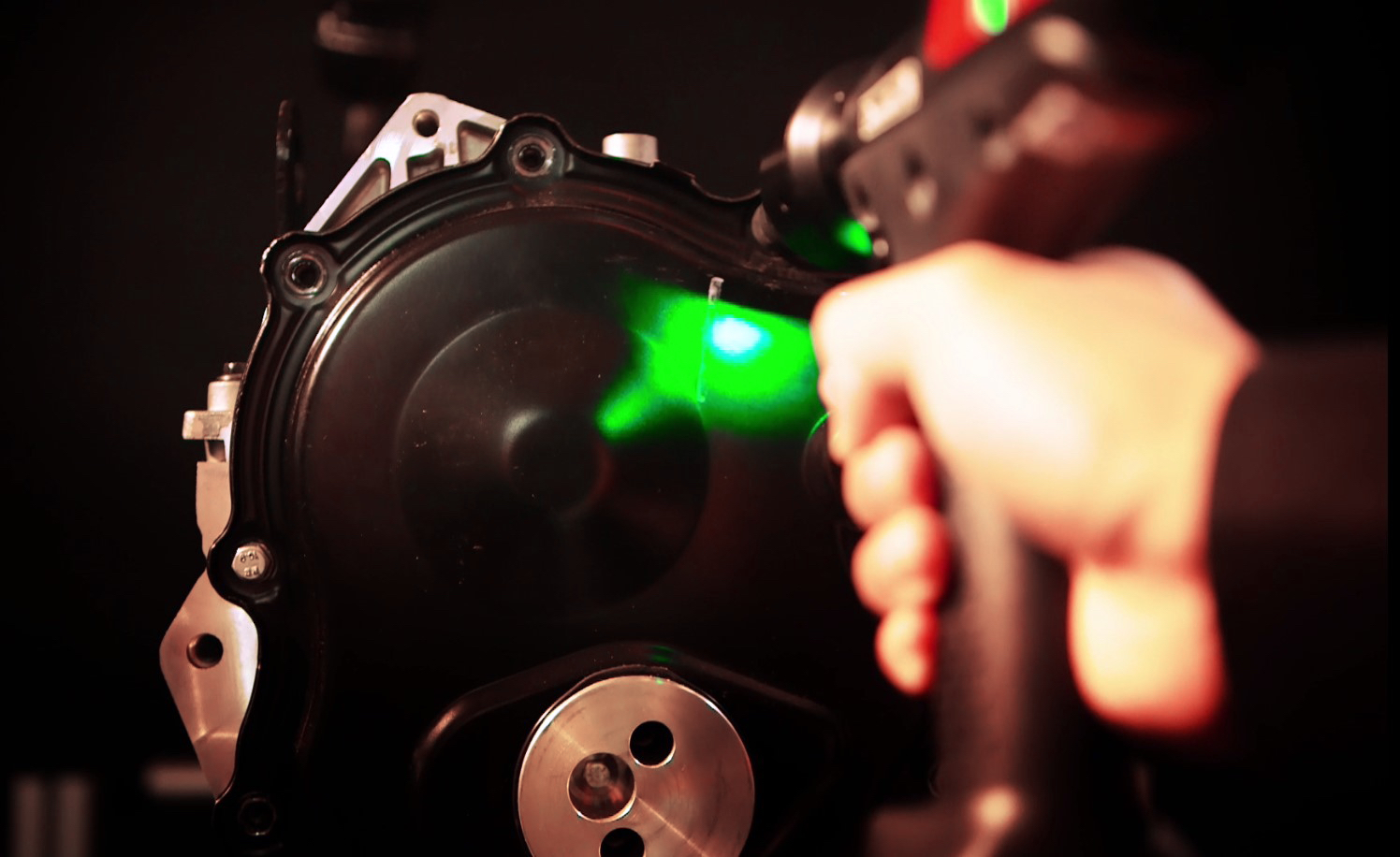

1. Measure dimensions

Having robot-compatible equipment that is capable of fast and non-destructive measuring dimensional characteristics. One use case could be for drilled holes in aerospace.

2. Check components

Checking the presence and position of components. For instance, by combining machine vision with machine learning software for controlling the correct position of various parts on a finished assembly.

3. In-line analysis

Conducting real-time analysis of results from various sensors. For example triggering alerts to the user and suggest corrective or preventive actions to improve the quality results.

Industrial Tool Identification with Atlas Copco

Atlas Copco Industrial Technique services over a million industrial power tools worldwide. We seek innovative solutions to make our tool identification and management more connected, efficient, and transparent.

Learn more

Virtual Workflow Training with Scania

Scania, a world-leading sustainable transport solutions provider, is now looking for solutions that enable simulated, safety-focused training for working with high-voltage batteries. If you work on solutions that will allow scalable, adaptable,…

Learn more

Autonomous Transport Systems with Scania

Scania, a world-leading provider of sustainable transport solutions, foresees a significant technology shift to autonomous vehicles in the transport and logistics ecosystem, leading to new business opportunities. We would like to hear…

Learn more