SKF is a world leader in rolling bearings and related technologies, constantly looking to increase the efficiency of their manufacturing processes. As part of this goal, we are now looking to address the energy consumption during idle time of production machines, particularly in significant energy consumers like grinding machines. The challenge is to minimize energy usage without compromising other productivity drivers such as quality or uptime.

Opportunity overview

Currently, several energy-consuming functions in production machines are running despite them being in idle mode. The priority lies in achieving significant reductions in idle mode energy consumption, especially on channel levels, across more than 50 bearing factories worldwide. Preliminary studies indicate that addressing short stops (<15 minutes) could potentially save 4-5 hours of energy consumption per week, per factory. Apart from potential cost savings, the initiative aligns with the broader efforts in environmental responsibility and optimizing energy usage across SKF industrial operations.

The desired solution should focus on minimizing idle mode energy consumption in grinding machines with PLCs/NCUs of various brands and models. Implementing intelligent software solutions that can automatically adjust machine functions during idle periods without extensive manual programming per machine could dramatically enhance the energy efficiency in the production lines. A critical factor lies in efficiently scaling the solution across a diverse range of grinding machines.

Examples we're looking for

Intelligent software solutions for PLCs/NCUs

Implementing intelligent software solutions that can automatically adjust machine functions during idle periods without extensive manual programming per machine could dramatically enhance the energy efficiency in the production lines. These solutions should offer scalability across different machine types and brands.

Method-based approaches to provide scalability

Exploring method-based approaches that prioritize scalability over specific technologies could be another avenue. This may involve developing standardized protocols or algorithms that can be easily implemented across various PLC/NCU systems with minimal software modification.

Energy Usage Optimization with Stora Enso

Stora Enso is looking for solutions to identify and optimize their energy consumption, alongside potentially other utilities such as compressed air, water, and chemicals in the production process. The primary objective is…

Learn more

Power Plant Advisor Tool for Operators and Engineers with Stora Enso

Stora Enso is seeking innovations to transform the efficiency of their power plants, specifically focusing on optimizing steam and electricity production and smart procurement from the spot market. The primary goal is…

Learn more

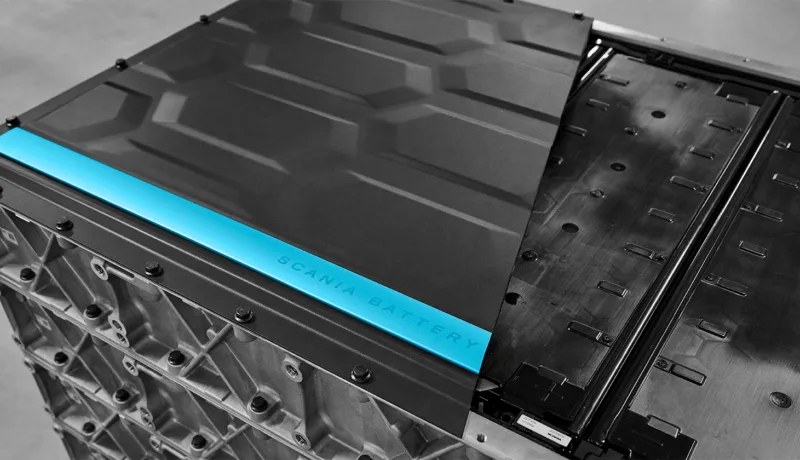

Battery Performance Enhancement with Scania

Scania has a key strategic focus on heavy vehicle electrification. Driven by the commitment to drive the shift towards a more sustainable transport system, Scania is looking to continuously enhance the performance…

Learn more